Soil resistivity testing is the single most critical factor in electrical grounding design. This is true when discussing simple electrical design, to dedicated low-resistance grounding systems, or to the far more complex issues involved in Ground Potential Rise (GPR) studies.

Soil Resistivity Testing

Soil resistivity testing is the process of measuring a volume of soil, to determine the conductivity of the soil. The resulting soil resistivity is expressed in ohm-meters or ohm-centimeters. Good soil models are the basis of all grounding designs and they are developed from accurate soil resistivity testing.

Wenner Soil Resistivity Test and Other Soil Resistivity Tests

The Wenner 4-Point Method (sometimes called 4-Pin) is by far the most used test method to measure the resistivity of soil. Other methods do exist, such as the General method and Schlumberger method, however they are infrequently used for grounding design applications and vary only slightly in how the probes are spaced when compared to the Wenner Method.

Electrical resistivity is the measurement of the specific resistance of a given material. It is expressed in ohm-meters and represents the resistance measured between two plates, covering opposite sides of a 1 m cube. This test is commonly performed at raw land sites, during the design and planning of grounding systems specific to the tested site. The test spaces four (4) probes out at equal distances to approximate the depth of the soil to be tested. Typical spacings will be in the range of 1’, 1.5’, 2’, 3’, 4.5’, 7’, 10’, etc., with each spacing increasing from the preceding one, by a factor no greater than 1.5, up to a maximum spacing that is approximately 1 to 3 times the maximum diagonal dimension of the grounding system being designed. This results in a maximum distance between the outer current electrodes of 3 to 9 times the maximum diagonal dimension of the future grounding system. This is one “traverse” or set of measurements, and is typically repeated, albeit with shorter maximum spacings, several times around the location at right angles and diagonally to each other to ensure accurate readings.

The basic premise of the test is that probes spaced at 5’ distances across the surface, will measure the average soil resistivity to an approximate depth 5 feet. The same is true if you space the probes 40’ across the earth, you get a weighted average soil resistance from 0’ down to 40’ in depth, and all points in between. This raw data must be processed with computer software to determine the actual resistivity of the soil as a function of depth.

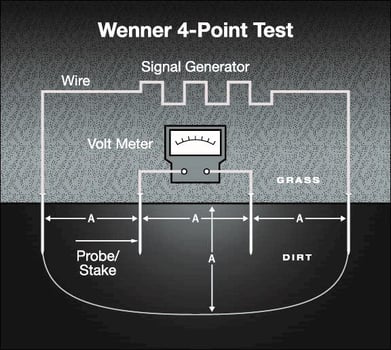

Conducting a Wenner 4-Point Test

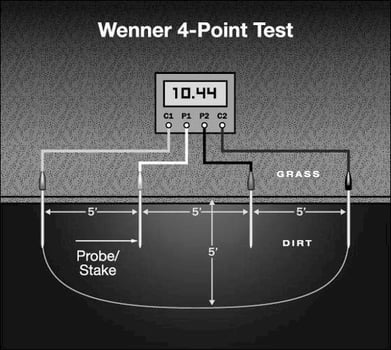

The following describes how to take one “traverse” or set of measurements. As the “4-point” indicates, the test consists of 4 pins that must be inserted into the earth. The outer two pins are called the Current Probes, C1 and C2. These are the probes that inject current into the earth. The inner two probes are the Potential Probes, P1 and P2. These are the probes that take the actual soil resistance measurement.

In the test shown in below, a probe C1 is driven into the earth at the corner of the area to be measured. Probes P1, P2, and C2 are driven at 5’, 10’ and 15’ respectively from rod C1 in a straight line to measure the soil resistivity from 0’ to 5’ in depth. C1 and C2 are the outer probes and P1 and P2 are the inner probes. At this point, a known current is applied across probes C1 and C2, while the resulting voltage is measured across P1 and P2. Ohm’s law can then be applied to calculate the measured apparent resistance.

Probes C2, P1 and P2 can then be moved out to 10’, 20’ and 30’ spacing to measure the resistance of the earth from 0’ to 10’ in depth. Continue moving the three probes (C2, P1 and P2) away from C1 at equal intervals to approximate the depth of the soil to be measured. Note, that the performance of the electrode can be influenced by soil resistivities, at depths that are considerably deeper than the depth of the electrode, particularly for extensive horizontal electrodes, such as water pipes, building foundations or grounding grids.

Soil Resistance Meters

There are basically two types of soil resistance meters: Direct Current (DC) and Alternating Current (AC) models, sometimes referred to as High-Frequency meters. Both meter types can be used for 4-point and 3-point testing, and can even be used as a standard (2-point) volt meter for measuring common resistances.

Care should always be given when selecting a meter, as the electronics involved in signal filtering are highly specialized. Electrically speaking, the earth can be a noisy place. Overhead power lines, electric substations, railroad tracks, various signal transmitters and many other sources contribute to signal noise found in any given location. Harmonics, 60 Hz background noise, and magnetic field coupling can distort the measurement signal, resulting in apparent soil resistivity readings that are larger by an order of magnitude, particularly with large spacings. Selecting equipment with electronic packages capable of discriminating between these signals is critical.

Alternating Current or High-Frequency meters typically use a pulse signal operating at 128 pulses per second or greater. Often these AC meters claim to be using “pulsed DC” which is in reality simply a square-wave AC signal. These Alternating Current meters typically suffer from the inability to generate sufficient current and voltage (typically less than 50 mA and under 10 volts) to handle long traverses and generally should not be used for probe spacings greater than 100 feet. Furthermore, the high frequency square wave signal flowing in the current lead induces a noise voltage in the potential leads, which cannot be completely filtered out: this noise becomes greater than the measured signal, as the soil resistivity decreases and the pin spacing increases. High-Frequency meters are less expensive than their Direct Current counterparts and are by far the most common meter used in soil resistivity testing.

Direct Current meters, which actually generate low frequency pulses (on the order of 0.5 to 4.0 seconds per pulse), are the preferred equipment for soil resistivity testing, as they do away with the induction problem from which the High-Frequency meters suffer. However they can be very expensive to purchase. Depending upon the equipment’s maximum voltage (500 to 2,000 mA and 800 volts peak to peak), Direct Current meters can take readings with extremely large probe spacings and often many thousands of feet in distance. Typically, the electronics filtering packages offered in Direct Current meters are superior to those found in Alternating Current meters. Care should be taken to select a reputable manufacturer.

Data Analysis

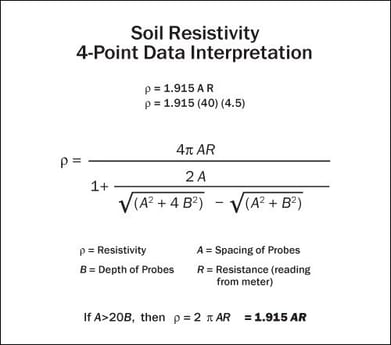

Once all the resistance data is collected, the following formula can be applied, to calculate the apparent soil resistivity in ohm-meters:

For example, if an apparent resistance of 4.5 ohms is measured at 40-foot spacing, the soil resistivity in ohm-meters would be 344.7. The figure on the left shows the entire soil resistivity formula in detail. One refers to “apparent” resistivity, because this does not correspond to the actual resistivity of the soil. This raw data must be interpreted by suitable methods in order to determine the actual resistivity of the soil. Also note that the final 1.915 number is calculated by converting meters into feet.

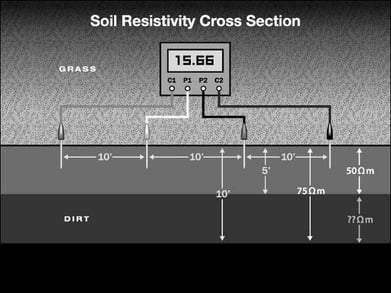

Often when we describe a Soil Resistivity test, such as the Wenner 4-Point Method, we correlate the spacings between the probes as a depth or sounding reading. In other words, the distance between the pins in theory equates to the approximate depth being measured. Remember that there are many factors that relate to the actual depth of the measurements read by the meter, so this concept is just a general guideline.

When a resistivity meter takes a measurement, that individual number means nothing in itself, without first doing a little math to determine resistivity. The simplified formula is to take the reading from the meter, multiply by the probe spacing (in feet), and then multiply it again by 1.915. The result is a resistivity number. When we combine a series of measurements taken at different spacings, we can begin to determine what the characteristics (resistivity) of the earth are like at various depths. The process of comparing numerous individual soil resistivity measurements (at differing spacings) is how one develops a “Soil Model”.

The soil model will show changes in resistivity of the earth at various depths. What is the resistivity of the soil at 1 meter? What is it at 10 meters? A good soil model will answer these questions. Of course, there are many rules as to how many measurements must be taken and at what spacings are required in order to get an accurate model, but that is a different topic. The concern in this case is what happens when a drastic change in resistivity occurs from one layer to the next.

As you can see from the Figure, if you have a 5’ reading of 50 ohm-meters and a 10’ reading of 75 ohm-meter soil, the actual soil resistance from 5’ to 10’ might be 100 ohm-meters (the point here is to illustrate a concept: pre-computed curves or computer software are needed to properly interpret the data). The same follows true for larger pin spacings. The shallowest readings are used over and over again in determining the actual resistivity at depth.

When we conduct a soil resistivity test, we are injecting a test signal (electrical energy) into the surface of the earth, down through the soil to various depths, and recording the loss of energy as a resistance. As the electrical test signal passes from one layer to the next, the test signal will degrade in proportion to the changes in resistance that it encounters. This is especially true when the signal must try to move from a very conductive layer of soil to a very resistive layer of soil. The test signal will simply prefer to stay in the most conductive material.

If you have ever seen a submarine war movie, the sub commander will move his submarine below a colder layer of ocean water, to avoid being detected by sonar. The cold layer of water will bounce the sonar signal up and away from the submarine, hiding it from the enemy. This is similar to what happens when conducting soil resistivity tests; the test signal may in fact not penetrate the layers as well as we might hope.

These changes in layer resistivity affect the signal in a predictable way, and as such can be calculated and its effects corrected. This is why good engineers prefer soil resistivity models calculated using computer modeling programs, instead of simple hand-calculations (good computer modeling programs perform thousands, if not hundreds of thousands, of calculations). Today’s sophisticated algorithms’ take into account most of the variables and provide vastly superior and more accurate soil resistivity models.

That said, computer algorithms can only help correct the math. A good soil resistivity technician will know how to improve the original signal. The first step is to always use true direct-current (DC) meters. It is recommended to use 800-volt p-p DC meters which require an additional car-battery to generate the needed power. The next step is to have many readings starting at 6-inch spacings, with spacing intervals increasing at a factor of no greater than 1.5, with 1.33 preferred. You would also need to keep taking readings and increasing your spacings at those intervals until your spacings are at least as great as the depth you are trying to read, preferably two or three times as great. This would certainly mean many dozens of measurements and a lot of work.

Shallow Depth Readings

Shallow depth readings, as little as 6” in depth, are exceedingly important for most, if not all, grounding designs. As described above, the deeper soil resistivity readings are actually weighted averages of the soil resistivity from the earth surface down to depth and include all the shallow resistance readings above it. The trick in developing the final soil model is to pull out the actual resistance of the soil at depth, and that requires “subtracting” the top layers from the deep readings. The following figure demonstrates how the shallowest readings impact deeper ones below it.

Shallow depth readings of 6-inches, 1-foot, 1.5-feet, 2-feet and 2.5-feet are important for grounding design, because grounding conductors are typically buried at 1.5 to 2.5-feet below the surface of the earth. To accurately calculate how those conductors will perform at these depths, shallow soil readings must be taken. These shallow readings become even more important when engineers calculate Ground Potential Rise, Touch Voltages and Step Voltages.

Shallow depth readings of 6-inches, 1-foot, 1.5-feet, 2-feet and 2.5-feet are important for grounding design, because grounding conductors are typically buried at 1.5 to 2.5-feet below the surface of the earth. To accurately calculate how those conductors will perform at these depths, shallow soil readings must be taken. These shallow readings become even more important when engineers calculate Ground Potential Rise, Touch Voltages and Step Voltages.

It is critical that the measurement probes and current probes be inserted into the earth to the proper depth for shallow soil resistivity readings. If the probes are driven too deep, then it can be difficult to resolve the resistivity of the shallow soil. Ideally a 20 to 1 ratio (5%) is best; however when doing very shallow readings that rule cannot always apply. A good rule of thumb when conducting short spacing measurements is that the penetration depth of the potential probes should be no more than 10% of the pin spacing, whereas the current probes must not be driven more than 30% of the pin spacing.

Deep Readings

Often, the type of meter used, determines the maximum depth or spacing that can be read. A general guideline is that alternating current soil resistivity meters are good for no more than 100 foot pin spacings, particularly in low resistivity soils. For greater pin spacings Direct Current soil resistivity meters are required. While direct current meters are always the preferred choice, they are the only type of meter that can generate the required voltages needed to push the signal through the soil at long distances free of induced voltages and signal noise error from the current injection leads.

Test Location

Soil resistivity testing should be conducted as close to the proposed grounding system as possible, taking into consideration the physical items that may cause erroneous readings. There are two (2) issues that may cause poor quality readings:

- Electrical interference, causing unwanted signal noise to enter the meter.

- Metallic objects ‘short-cutting’ the electrical path from probe to probe. The rule of thumb here is that a clearance equal to the pin spacing should be maintained, between the measurement traverse and any parallel buried metallic structures.

Testing in the vicinity of the site in question is obviously important; however, it is not always practical. Many electric utility companies have rules regarding how close the soil resistivity test must be, in order to be valid. The geology of the area also plays into the equation, as dramatically different soil conditions may exist only a short distance away.

When left with little room or poor conditions in which to conduct a proper soil resistivity test, one should use the closest available open field, with as similar geological soil conditions as possible.

Let's Talk! Schedule a FREE Phone Consultation Today.

Wherever you're located, learn how good a fit we are for your project.