Ground / Earthing rods (electrodes) are typically comprised of steel with a thin coating of copper or zinc (galvanized) to protect the steel from excessive corrosion. Copper-bonded ground rods are coated with copper with a thickness that ranges between 1.5 to 10 mils (0.0015 to 0.010 inches). Galvanized ground rods are typically coated with zinc to a thickness of around 3.9 mils or 0.0039 inches.

When standard copper-clad carbon steel ground rods are installed, they are generally driven into the earth with a hammer or some other form of mechanical pounding device. The tensile strength of standard ground rods range from 58,000 psi to 90,000+ psi, which is important to prevent “mushrooming” of the head of the rod when hammering it into the earth. Some people call this the “drivability” of the ground rod. Stainless steel ground rods can have tensile strengths as high as 85,000 psi and typically can be driven into the earth similarly to a standard ground rod. Solid copper rods are often structurally too weak to be driven into the earth with a hammer system, thereby requiring pre-drilling. The hammering action scrapes the very thin copper coating off, exposing the steel to the corrosive soil. As such, the typical thin-coated copper-clad and galvanized ground rod can be expected to last between 10 to 13 years, depending upon the soil conditions. A copper-clad steel ground rod with a 10 mil (0.010 inches) copper coating is claimed to last as long as 30 years. Stainless steel and solid copper rods require no such coatings and as such have longer-life spans, easily exceeding 50+ years of service life.

Note: Galvanized ground rods tend to have shorter life spans in soil conditions where salt is present (copper-clad lasts longer when salt is in the soil).

Ground Rod Diameters

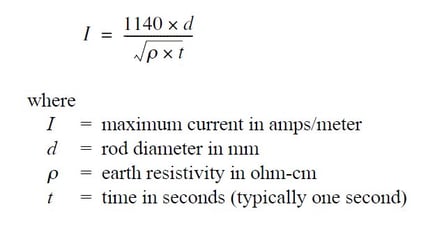

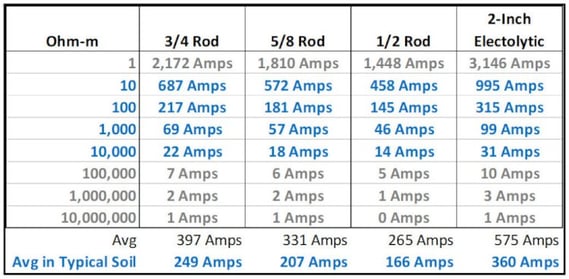

The diameter of the ground rod not only makes the “drivability” of the ground rod better, it also is the primary factor in determining the current-handling capacity of the ground rod, or “ampacity” of the electrode. If we look at IEEE Std.-142-2007 Chapter 4.1.6 we see that the current-loading of a ground rod can be calculated with the following formula:

This can then be equated to show the ampacity of various electrodes in a given soil as shown in the chart below:

Electrode Ampacities in Various Soils.

A good “Rule of Thumb” is to say that a single ground rod can handle between 100 to 200 amps of current.

Ground Rod Spacing:

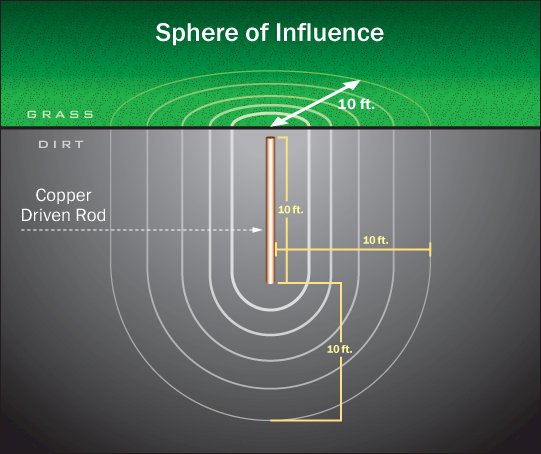

Ground rods should not be installed to close to each other. The Nature of Grounding Resistance of “sphere-of-influence theory” (IEEE Std.-142-2007 Chapter 4.1.2), tells us that a given electrode will utilize a volume of soil around the electrode that is roughly equal to the length of the rod.

Nature of Grounding Resistance

This means that ground rods should be spaced outside of each other’s sphere-of-influence in order to maximize the benefits of the electrodes. In other words, you should not space electrodes so close that the sphere-of-influence of the first electrode falls within the sphere-of-influence of the adjacent rod.

For a 10-ft long ground rod, the closest the next ground rod should be spaced is 20-ft away.

The National Electrical Code (NEC) tells us that ground rods should be ideally spaced at a minimum distance of 2x their length. See NEC Article 250.53(A)(3) Informational Note.

Let's Talk! Schedule a FREE Phone Consultation Today.

Wherever you're located, learn how good a fit we are for your project.