The best way to protect people from electric shock and equipment from objectionable electrical damage, is to bond all exposed-conductive-parts together and ground/earth them to a single common electrode system to ensure that there are no differences in potential.

This basic principle of electrical safety for people has been the guiding objective of grounding and earthing in electrical engineering since the time of Thomas Edison and Nikola Tesla. So why is it that electrical grounding, earthing, and bonding are such a mystery to so many?

Truly, the biggest issue in human safety in electrical engineering projects is not getting grounding experts involved at the early stages of a project so that they can help find the correct grounding/earthing solution for your clients.

Here is a list of the Top 3 Mistakes People Make with Grounding & Earthing Projects:

#1 Cookie-Cutter Grounding Designs without Understanding the Goals of the System

What is the purpose of the grounding system for your site? An airplane has an extensive grounding system, its purpose is to reduce the difference in potential across the metallic components of the plane to near zero so that it can safely handle in-flight lightning strikes, along with other electronic systems requirements.

What is the purpose of a grounding system for a substation? Electrical substations often have two (2) primary goals for its grounding and earthing systems: First to protect personnel from hazardous step & touch voltages (see 29 CFR 1910.269 and IEEE Std. 80), and second to provide a mechanism for fault-currents to travel through the earth/soil. At the level of substations and powerplants, the NESC allows the use of the earth as a conductor and may be part of the fault-current path for transformers.

What is the purpose of the grounding system for some antennae, satellite dishes, plasma-cutters, and MRI machines? Some pieces of equipment utilize the grounding system as part of its actual circuity and a low resistance-to-ground is critical for its proper operation.

What is the purpose of grounding for variable frequency drives (VFD), surge protection devices (SPD), and devices requiring isolated grounds? What is the purpose of the grounding systems at data and computer centers? How do you protect these systems from lightning?

Does the incoming utility transformer for your site use your grounding system to clear its electrical faults back to the source utility? If so, you could be responsible for ensuring the electrical safety of your personnel under 29 CFR 1910.269 App C.

Does your fence require grounding per the National Electrical Code (NEC) Article 250.191 and 250.194?

Does your site have heavy robotics, special electronic systems, or computer servers that may need additional grounding systems to provide protection from electromagnetic interference?

Does your site have flammable liquids or other explosives? Do you need isolation transformers, perhaps a zig-zag transformer to help clear electrical faults locally?

Obviously, the list of items that may need specialized grounding and earthing goes on and on, and the liability related to those electrical safety and equipment operations is high. There are no cost-effective cookie-cutter designs that will meet every possible scenario.

#2 Not Considering the Entire Scale and Scope of Grounding

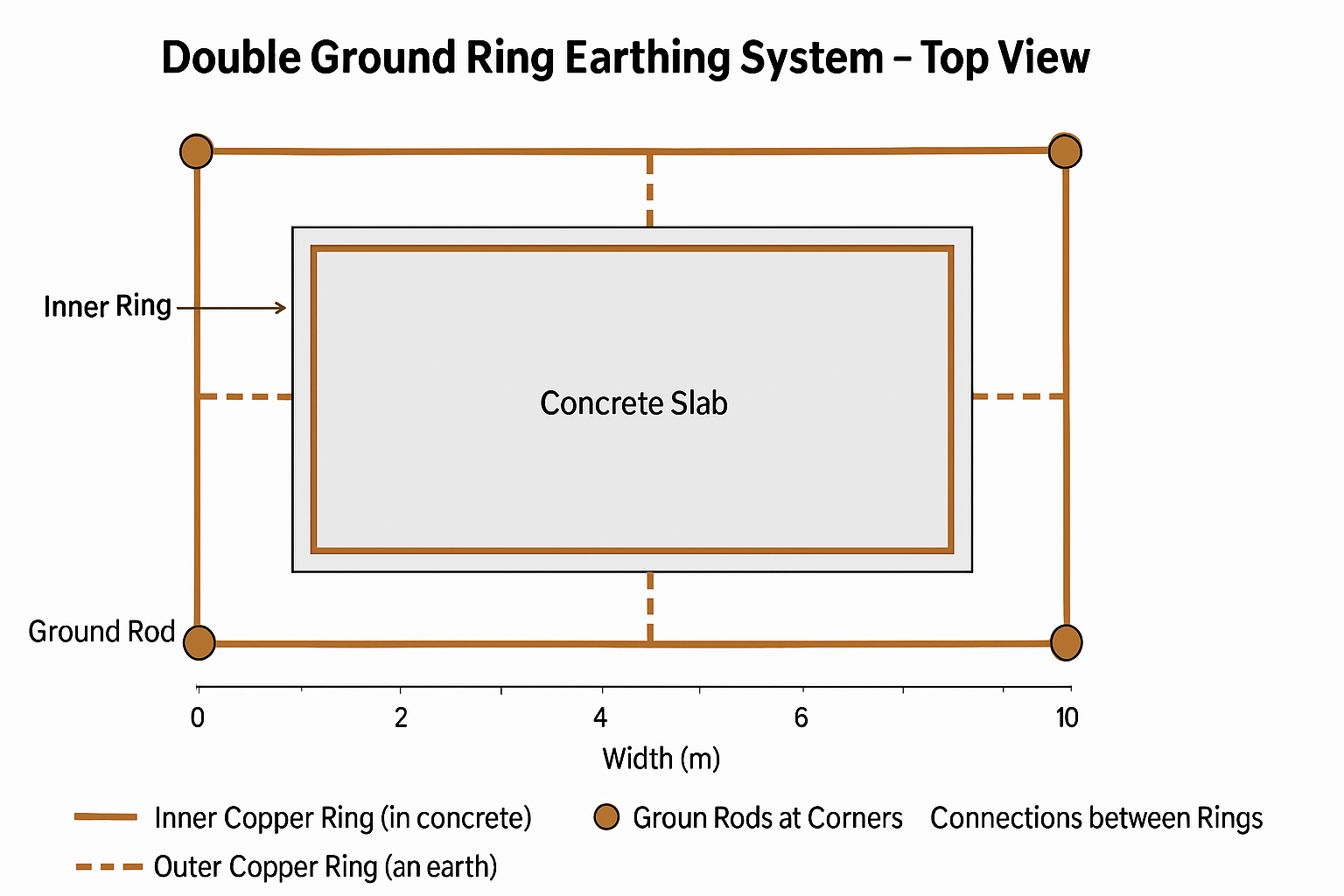

Take a moment to consider the building you are sitting in now. How many current-carrying conductors are there in the entire building? Now, think about how many grounded or earthed conductors there are… For most electrical circuits, you have a single (1) hot conductor, and two (2) grounded/earthed conductors. That’s two-thirds of the conductors that are grounded/earthed! Add to that list, the shield wires in Coax, CATV, CAT5/6 cables, alarm system, and other telco and data lines. Now add any Lightning Protection Systems, the steel rebar in your foundations, building steel, electrical conduit and raceways, water pipes, swimming pool equipotential grounds, gas pipes, and fire sprinkler systems. You may have special grounding systems for sensitive electronic systems, and equipotential grids for your industrial equipment, isolated grounds, special data system grounds, and even isolation transformers. Of course, don’t forget about every single touchable metal object in your structure! And we haven’t even mentioned your grounding and earthing electrode systems such as ground rods, ground plated, ground rings, electrolytic electrodes, concrete-encased electrodes, etc. All these components make up the structure of your grounding and earthing system, and it is far more extensive than any set of phase/hot wires.

Here at E&S we see time and time again, waisted cost-savings in projects where a little pre-planning could save the client tens of thousands of dollars! For example:

- Projects where the physical location of the buried grounding system is not even considered when thinking about the future above grade connections that will eventually be needed.

- Projects where columns and footings that could have been utilized for lightning protection down conductors and grounding electrodes for a few dollars in materials, end up costing the client thousands later just to have ugly external LPS installations with less overall benefit to the client.

- Projects with extensive steel rebar networks installed in concrete just inches below the floor of robotic factories not being utilized as a low-cost and highly-effective equipotential grid for fractions of the cost of installing an equipotential grid above-grade later.

- Projects with sensitive electronic systems that could have benefited not only from a dedicated electrode system, but from an isolation transformer, all of which could have easily been cost-effectively installed during original design/construction, but now costs tens of thousands of dollars later.

- Project where the grounding system must meet an engineering specification such as resistance-to-ground, but the A&E firm did not do their calculations and instead placed the burden on the electrical installer to test and amend the grounding system to meet the specification, resulting in cost overruns, delays, and unnecessary compromises in the sites primary electrical safety infrastructure system: grounding.

We could go on and on listing example after example, but by now you should get the point. Early and regular involvement during the design phase is the key to ensuring proper engineering. And engineering, when done correctly, provides the most cost-effective solutions to the client.

#3 Incorrect Wiring of Neutral-to-Ground Bonds Resulting in Electrocutions

Arguably, one of the most misunderstood parts of the National Electrical Code (NEC) is Article 250.24(B) “Main Bonding Jumper” and 250.28 “Main Bonding Jumper and System Bonding Jumper”.

The Code has simply done a great disservice to the electrical world by failing to provide clear and comprehensive instructions within the Code for when a neutral-to-ground bond outside of a transformer is needed, and when it is not. Unfortunately, this failure to provide clear guidance has resulted in numerous electrocutions and deaths.

The primary concern is that when ever a neutral-to-ground bond is placed in panel (outside of the transformer itself), it can allow objectional currents to flow in violation of NEC Article 250.6. Objectionable Currents are when normal neutral currents, that should be on the Neutral Conductor, are allowed to travel through touchable normally-non-current-carrying objects.

Meaning, that during normal operations, not when a fault is occurring, but when the system is running at peak operations; hazardous currents that should be returning to the transformer on the insulated neutral conductors, are instead traveling back on exposed and touchable metallic objects. We call these hazardous currents, “objectionable currents” and they are very dangerous.

This issue really requires the Code writers to sit down and revamp huge portions of the code, a full and complete re-write of much of Part III of the Article 250. Instead of doing this, or instead of simply mandating that the utility bring a ground conductor into the service, the Code writers have gone to great lengths to avoid a full re-write and have scatter-shot bits of Code all over Article 250 and even more in the Handbook, to prevent Objectionable currents. They have failed.

For example, the Code tells us when and how to use a NTG Bond in the following places:

- 250.24(B)

- 250.28

But then, the Code provides exceptions and exclusions to the above two Codes in at least thirteen (13) different places. Here is a list of where the code tells us when NOT to use a NTG Bond:

- NEC Articles 250.6(B)

- 250.24(A)(5) HB Notes

- 250.30 HB Notes “Application Examples 1, 2 and 3”

- 250.30(A)

- 250.30(A) HB Notes “Common Misconception”

- 250.30(A)(1)

- 250.30(A)(1) Exception #2

- 250.30(A)(1) Exception #3 (a) and (b)

- 250.30(A)(5) HB notes

- 250.32(B)(2)(b)

- 250.32(B)(1) HB notes

- 250.142(B)

- HB Exhibit 250.8

You will note that the Code writers are relying heavily on the commentary within the Handbook (HB) to correct the poorly written code in 250.24(B) and 250.28. Unfortunately, electricians are taught that the commentary in the Handbook is not code, but just guidance. This results in one of the most common mistakes people make in their grounding systems, they design a system with hazardous objectionable currents.

So why the confusion? Well, it is the same age-old answer for just about every problem we encounter in engineering: money.

There is a common saying that goes, “Any idiot can build a bridge that stands, but it takes an engineer to build a bridge that barely stands” - anonymous.

While the above quote may seem like a fictitious exaggeration, it does make a great point: both under-designing and overdesigning are not good engineering.

This is exactly what we find when it comes to the neutral-to-ground bond in our service panel. Why is there? Well, it is there because the Utility did no want to pay for a ground wire from the transformer to your structures service panel. That’s the reason. All of those codes listed above, all of the confusion, all of the deaths, all to save a few bucks in wire costs.

Take a minute to think about the service that comes into your home. In the USA, it probably comes from an overhead utility pole and contains two (2) copper wires, and a steel guy wire. The two copper wires are your phase wires (hot wires). That steel guy wire has to do three (3) jobs: It has to be the return path for the neutral currents, it has to be the ground-fault-current path should an electrical fault occur, and it has to be the support wire for the other two conductors.

Now, some places in the USA do in fact run three (3) copper wires, two (2) phase wires, and one (1) neutral wire, in addition to the supporting guy-wire. All three (3) are normally-current-carrying conductors. However, the neutral wire still has to two (2) jobs: it has to be the return path for the neutral currents, and it has to be the ground-fault-current path should an electrical fault occur.

If the utility company were to bring over a normally-non-current-carrying ground wire along with its normally-current-carrying wires, you would not need a neutral-to-ground bond in your cabinet, as the neutral wire would only have one (1) job: be the return path for neutral currents. The new ground wire would have the job of being the fault-current path should an electrical fault occur.

Imagine for a moment an electrical code that simply mandated a dedicated ground wire from every transformer, including the utility company’s transformers, and forbid neutral-to-ground bonds anywhere outside of the transformer. Wouldn’t that be easy? And it would be safer, and it would cost less money in your electrical bill too (passing current through a steel guy wire is expensive)!

Our electrical systems should have dedicated fault-current paths. We should not rely on our structural building steel or on our neutral wires to be part of that path, any more than we should be using our building's structural supports as our sole electrode system.

It’s the 21st century and we can do better than what was done in the 19th century.